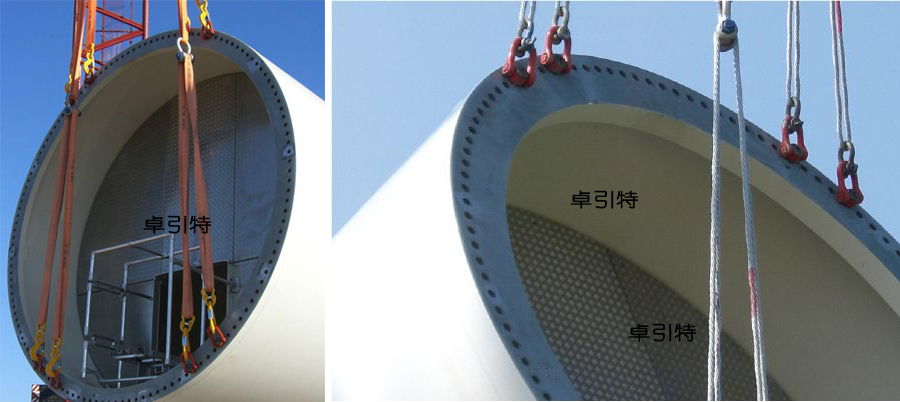

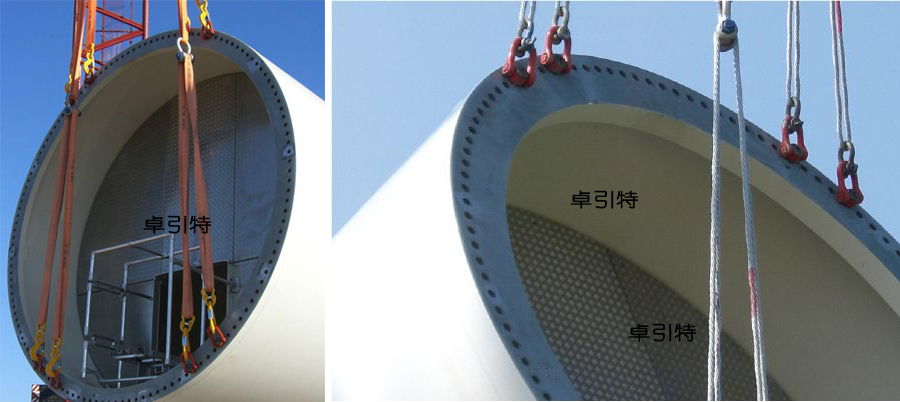

●广泛应用于汽车模具制造业、风电设备、机械电气设备等领域。

●产品载荷为最不利角度下的载荷,安全系数4:1,符合欧盟EN-1677要求。

●采用进口高强度合金钢锻制,提供产品测试报告证书。

●请根据需要选择合适的万向旋转吊环,请勿超过额定载荷,万向旋转吊环上刻有额定载荷。

●工件表面必须平整,以使吊环与工件表面全接触,中间不得有间隙。

●安装完毕后,万向旋转吊环上端的长环不可碰触到被吊物或其它物体。

●起吊时,请匀速施加载荷,逐渐加力,勿施加冲击载荷及振动载荷。

●万向旋转吊环不适合满载时高速旋转。

●可定制加长螺纹杆。

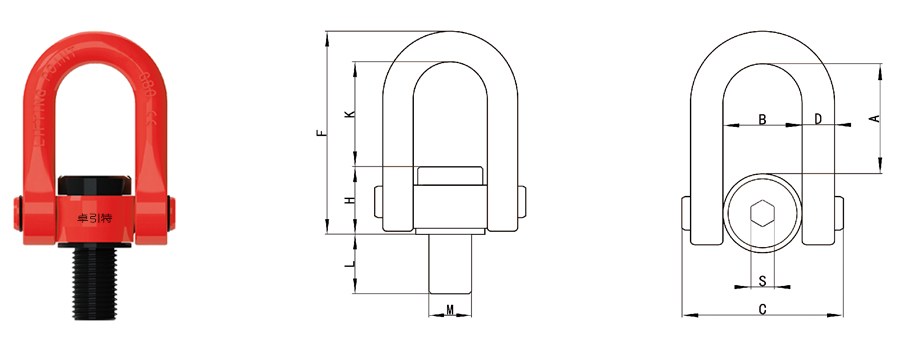

公制螺纹

|

规格型号 |

额载 |

尺寸 mm |

锁紧扭矩 |

自重 |

|

T |

L |

A |

B |

C |

D |

F |

K |

M |

H |

S |

Nm |

kg |

|

HR125-M8×1.25 |

0.5 |

12 |

48.5 |

37 |

76 |

14 |

103.5 |

49.5 |

8 |

40 |

8 |

30 |

0.8 |

|

HR125-M10×1.5 |

0.7 |

16 |

48.5 |

37 |

76 |

14 |

103.5 |

49.5 |

10 |

40 |

8 |

60 |

0.8 |

|

HR125-M12×1.75 |

1 |

18 |

48.5 |

37 |

76 |

14 |

103.5 |

49.5 |

12 |

40 |

8 |

100 |

0.8 |

|

HR125-M14×2.0 |

1.5 |

21 |

48.5 |

37 |

76 |

14 |

103.5 |

49.5 |

14 |

40 |

8 |

120 |

0.8 |

|

HR125-M16×2.0 |

2 |

24 |

48.5 |

37 |

76 |

14 |

103.5 |

49.5 |

16 |

40 |

8 |

150 |

0.8 |

|

HR125-M20×2.5 |

3 |

40 |

73 |

54 |

106 |

20 |

151 |

77 |

20 |

54 |

12 |

250 |

2 |

|

HR125-M24×3.0 |

4.5 |

40 |

73 |

54 |

106 |

20 |

151 |

77 |

24 |

54 |

12 |

400 |

2.5 |

|

HR125-M30×3.5 |

7.3 |

45 |

98.5 |

74 |

149 |

30 |

206.5 |

103.5 |

30 |

73 |

17 |

500 |

5.5 |

|

HR125-M33×3.5 |

8 |

50 |

98.5 |

74 |

149 |

30 |

206.5 |

103.5 |

33 |

73 |

17 |

800 |

5.5 |

|

HR125-M36×4.0 |

10 |

54 |

98.5 |

74 |

149 |

30 |

206.5 |

103.5 |

36 |

73 |

17 |

1000 |

5.5 |

|

HR125-M39×4.0 |

10 |

58 |

98.5 |

74 |

149 |

30 |

206.5 |

103.5 |

39 |

73 |

17 |

1200 |

6 |

|

HR125-M42×4.5 |

12.5 |

63 |

98.5 |

74 |

149 |

30 |

206.5 |

103.5 |

42 |

73 |

17 |

1500 |

6 |

|

HR125-M48×5.0 |

20 |

68 |

117.5 |

93 |

183 |

36 |

255 |

122 |

48 |

93 |

19 |

2000 |

11.5 |

|

HR125-M52×5.0 |

20 |

68 |

117.5 |

93 |

183 |

36 |

255 |

122 |

52 |

93 |

19 |

2000 |

12 |

|

HR125-M56×5.5 |

25 |

78 |

117.5 |

93 |

183 |

36 |

255 |

122 |

56 |

93 |

19 |

2100 |

12 |

|

HR125-M64×6.0 |

32 |

90 |

117.5 |

93 |

183 |

36 |

255 |

122 |

64 |

93 |

19 |

2200 |

13 |

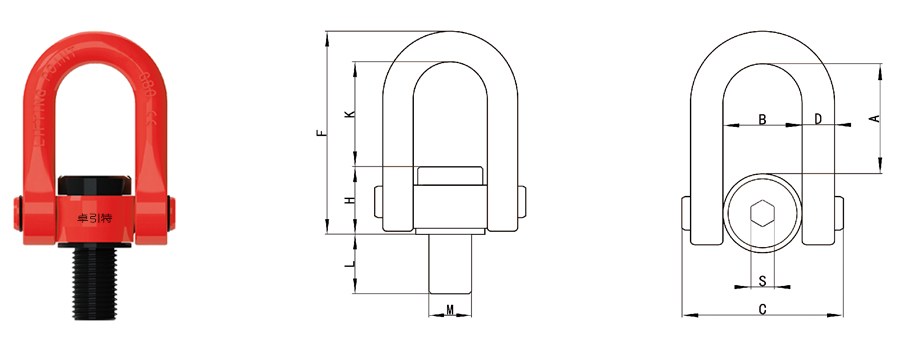

UNC螺纹

|

规格型号 |

额载 |

尺寸mm |

锁紧扭矩 |

自重 |

|

T |

L |

A |

B |

C |

D |

F |

K |

M |

H |

S |

Nm |

Kg |

|

HR125-5/16-18UNC |

0.5 |

12 |

48.5 |

37 |

76 |

14 |

103.5 |

49.5 |

8 |

40 |

8 |

30 |

0.8 |

|

HR125-3/8-16UNC |

0.7 |

16 |

48.5 |

37 |

76 |

14 |

103.5 |

49.5 |

10 |

40 |

8 |

60 |

0.8 |

|

HR125-7/16-14UNC |

1 |

18 |

48.5 |

37 |

76 |

14 |

103.5 |

49.5 |

12 |

40 |

8 |

100 |

0.8 |

|

HR125-1/2-13UNC |

1.5 |

21 |

48.5 |

37 |

76 |

14 |

103.5 |

49.5 |

14 |

40 |

8 |

120 |

0.8 |

|

HR125-5/8-11UNC |

2 |

24 |

48.5 |

37 |

76 |

14 |

103.5 |

49.5 |

16 |

40 |

8 |

150 |

0.8 |

|

HR125-3/4-10UNC |

3 |

40 |

73 |

54 |

106 |

20 |

151 |

77 |

20 |

54 |

12 |

250 |

2 |

|

HR125-1-8UNC |

4.5 |

40 |

73 |

54 |

106 |

20 |

151 |

77 |

24 |

54 |

12 |

400 |

2.5 |

|

HR125-1-1/4-7UNC |

8 |

50 |

98.5 |

74 |

149 |

30 |

206.5 |

103.5 |

33 |

73 |

17 |

500 |

5.5 |

|

HR125-1-1/2-6UNC |

10 |

54 |

98.5 |

74 |

149 |

30 |

206.5 |

103.5 |

36 |

73 |

17 |

1200 |

5.5 |

|

HR125-1-3/4-5UNC |

15 |

63 |

98.5 |

74 |

149 |

30 |

206.5 |

103.5 |

45 |

73 |

17 |

1500 |

5.5 |

|

HR125-2-4.5UNC |

20 |

68 |

117.5 |

93 |

183 |

36 |

255 |

122 |

52 |

93 |

19 |

2000 |

11.5 |

|

HR125-2-1/2-4UNC |

32 |

90 |

117.5 |

93 |

183 |

36 |

255 |

122 |

64 |

93 |

19 |

2200 |

12 |